AI Driven Solutions - Real World Case Study

AI Driven Solutions - Real World Case Study

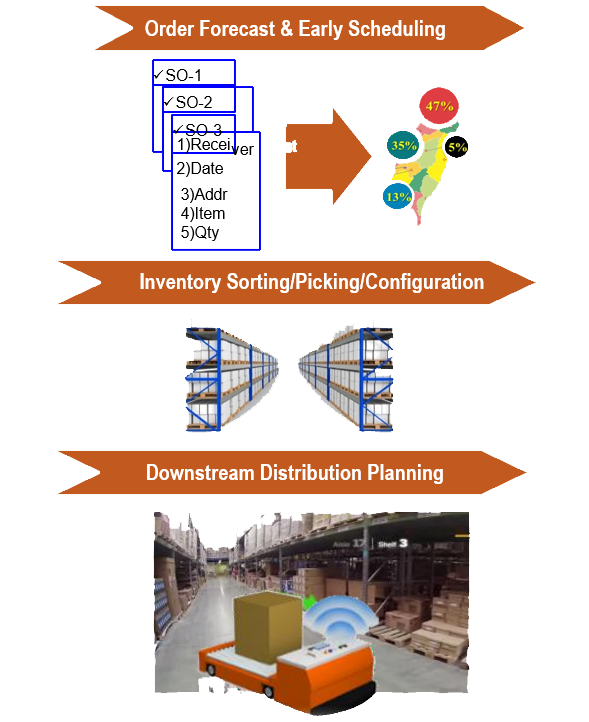

1. AI Driven Forecasting, Managing, & Distributing

Problems:

- Huge amount of online orders

- Frequent urgent shipments

- Constant labor shortage

Solutions:

- Demand Forecast Analysis

- Increase inbound/outbound shipment forecast accuracy from 75% to 95%

- Picking Configuration System

- Save 53% time and 71% distance

- Route Planning System

- Shorten order processing time

- AI Picker (Digital Assistant)

- Less time spent & less paper waste

2. AI Driven High-density High Speed Shuttle Rack System

Problems:

- Labor shortage

- Warehousing has been traditionally labor-intensive industry, estimated 50~70% labor; 60% time, 65% expense, and often marked by large error range, low efficiency.

- Increased demand on shorter response time from retailers and consumers

Solutions:

- AI High-density Warehouse/Inventory System

- AI algorithm conducts complex network flow planning to improve the sorting speed on millions of items.

- Allow products for the same order in different sorting areas (large & small cargo areas) to arrive at the shipping area at the same time

3. Cold Chain Tracking/Control System and Equipment

Distribution Tracking & Quality Management

Product Types/Temperature Traceability

Cooling Equipment Managing

Trucking Schedule Management

4. Cold Hold Items Temperature Control Tracking Platform

Problems:

- Difficult to control temperature, frequent errors on temperature settings, poorly conditioned facilities, harmful environmental impact, cold-hold required temperature loss, and incomplete order processing

- Cooling requirement of certain temperature for different products varies and it needs to be maintained systematically

Solutions:

- 24/7 real-time temperature updates

- Cold-Hold control in transit and storage

- Immediate signal irregular condition

- Sensor controlled tracking and warning

- Instant information should error occurs

- GPS signal tracking

5. High Speed Scanning for Measuring Size & Weight

Problems:

- High cost of importing ready-to-use measuring device

- Labor shortage

- Using manual or semi-automatic measuring devices yields low efficiency, very time-consuming, labor-intensive and has large errors.

Solutions:

- Instantly measure the volume and weight on a conveyor belt running at a high speed

- Adopt image recognition (1st generation) and advanced linear optical sensing technology (2nd generation)

- Record objects information and run computation

- Meet the need of EC for rapid mass sorting/measurement

- Give precise freight information and increase efficiency by 300%+

6. Intelligent AGV System for Open Space Warehouse

Problems:

- Goods in logistics centers are often piled up and messy. It takes time to look for or sort goods.

- The personnel need to confirm the distribution area of each item manually before sort out each item one by one.

- It is difficult for Ground-type AGV to locate and carry goods.

Solutions:

- Intelligent Automated Guided Vehicle (iAGV)

- Adapt to temporary obstacles on the ground

- Have a circulation engine that optimizes computation and avoid, which greatly improves efficiency

- Ceiling Navigation System, the world’s first with global patent

- Completed patent filing; win ICT Month Innovative Elite 2018

7. Platform & Stations Sharing

Problems:

- With rapid growth of eCommerce and a low first-time delivery rate, 10% of home parcels based on 100,000/day, need second time delivery

- Numerous incomplete deliveries due to various reasons

- Temporary parking in populated area causes extra expenses due to parking tickets.

Solutions:

- Shared Intelligent Pickup Service Platform across entire region

- With 24hr service, intelligent pickup stations support businesses that close early

- Promote the mix of pickup, sale, and display storage Introduce convenient shared sites among more communities

- Reduce vehicle parking and delivery time and improve personnel and traffic safety

- Increase the flexibility of delivery and billing

Problems:

- Highly volatility of demand from downstream retailers

- Various restrictions on delivery time

- Frequent changes of delivery routes

Solutions:

- Scheduling process is 65% shortened by using AI Driven Routing System (iRouting)

- Complete distribution scheduling service – vehicle scheduling, route planning, scheduling for 10,000 delivery points

- Shift the focus from driver experience to autonomous control

- Balanced route/shipments/points, work and rest, legal working hours Improve the distribution efficiency by 20%

- Reduce the delivery error from ±1 hour to ±10 minutes

- Reduce costs by 30%+

Problems:

- Supply and demand information is not transparent. Outbound vehicles are about 2/3 of inbound vehicles; the empty rate of returning vehicles is about 1/2; the average loading rate of shipments in some areas is low.

- Unable to plan for re-schedule caused by often changed circumstances during weekends or holidays

- Low and inconsistent investment in cold-hold transport and storage equipment

Solutions:

- Urban Logistics Sharing Platform - Match supply and demand to improve resource utilization, efficiency increased by 20%

- Systematically guiding logistic companies toward transportation equipment sharing

- Integrate small and medium cargo carriers to improve the overall quality of cold chain logistics service

- Instantly report on traffic status; increase the vehicle loading rate; reduce carbon emissions by 20% and logistics costs by 17%

10. Vertical Cross Belt Sorting System for Large Quantity Items

Problems:

- Picking time accounts for 60% delivery time, and 70% of manpower

- Lack of manpower, high error rate, low efficiency

Solutions:

- Region’s first visually vertical Cross Belt Sorter

- Have a distribution system with ultra-high speed, small occupancy, and high elasticity

- Ergonomic Smart Automated Sorting

- Create a good working environment and reduce turnover

- Reduce the demand for labor by 65% from 70 hires down to 22

- Significantly increasing the sorting speed from 3,600 pieces/hour to 12,000 pieces/hour

Problems:

- Manually schedule and confirm distribution orders by workers’ often unreliable experience

- Unplanned extra time spent during delivery

- Repeated manual input of changed schedule due to traffic jams or other problems

- Search maps or ask people for directions

- 2nd-time distribution is time consuming.

- Manually input confirmation and status after delivery

Solutions:

- Daily vehicle scheduling time is reduced by 30 minutes.

- Time to check the recipient address of a delivery is saved by 2 minutes. Given about 150 deliveries per day and 50% of the recipient addresses that are repeated or adjusted, 1~2 hours can be saved.

- If the hourly salary is $20 per labor,$50 can be saved per day, total $ 12,500 can be saved for each labor hired per year , based on 250 working days a year.

Join our monthly email list to watch videos of our latest automation projects.

You can unsubscribe anytime.