● MACHINE ●

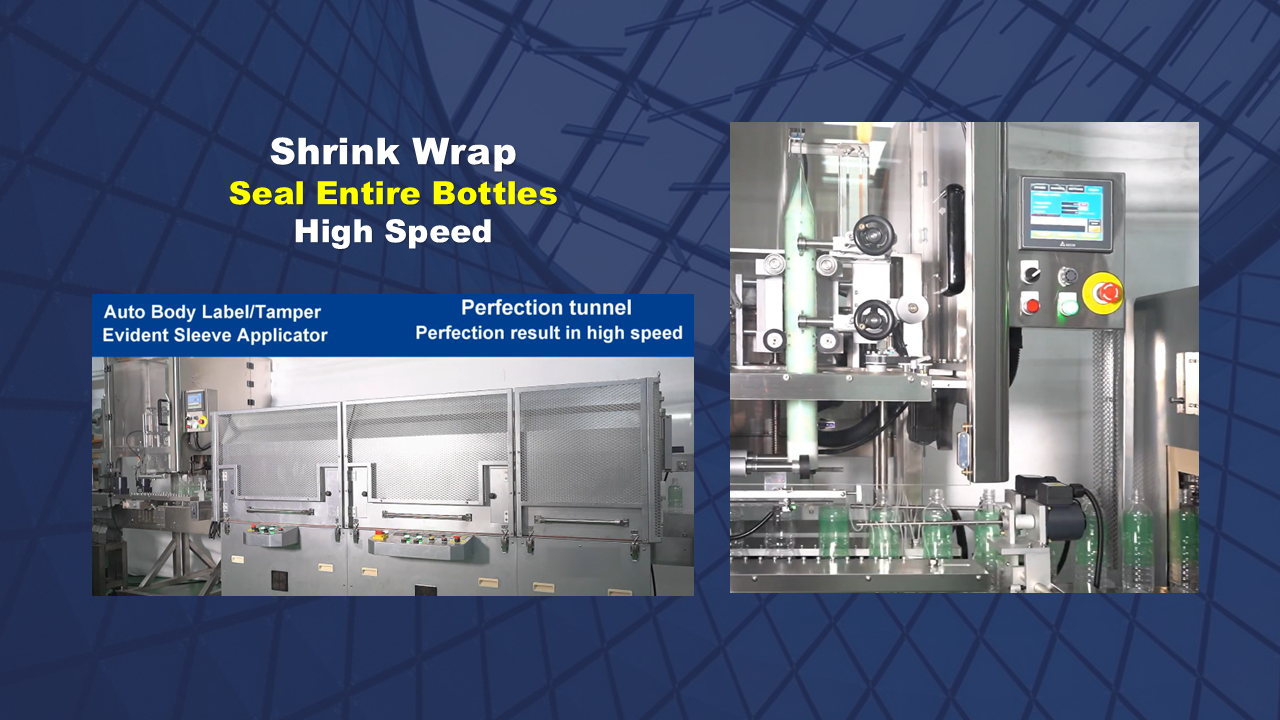

Shrink Sleeve Oil Roller Bottles (Oval & Round)

* Unscramble, Organize, Shrink Sleeve Roller Bottles |

● MACHINE ●

Shrink Wrap 32 of 7oz Yogurt Cups

* Cups are fed into 8 parallel lines for processing |

● MACHINE ●

Line of Cartoning - Handle a Variety of Products & Boxes

* Unfold & Bottom Seal Carboard Boxes |

● MACHINE ●

360-degree Wrap-around Labeling, Vertical Cartoing, Edges Top Labeling

* 360-degree Wrap Around Labeling |